In modern electrical systems, the power factor (PF) is a critical metric for measuring energy efficiency. When current and voltage waveforms are out of phase, reactive power losses occur, increasing grid load and reducing transmission efficiency. Power Factor Correction (PFC) technology aligns the current waveform with the voltage waveform, boosting the power factor close to 1. This delivers three key benefits:

Energy Efficiency: Reduces reactive power losses, maximizing actual power utilization in devices.

Grid Protection: Minimizes harmonic pollution, complying with global standards like IEC 61000-3-2 and US regulations such as the DOE’s Energy Conservation Standards.

Cost Savings: Lowers line losses, extends equipment lifespan, and cuts operational costs—especially crucial for large-scale US applications like data centers and industrial facilities.

Passive PFC uses passive components like inductors and capacitors to adjust current waveforms. It relies on a large silicon steel inductor and filter capacitors (LC circuit) to compensate for phase differences. Key characteristics include:

Advantages:

Affordable: No complex control circuits, making it cost-effective for budget-oriented devices.

Reliable: Simple structure with no active components, reducing failure rates.

EMC-Friendly: Passive components generate minimal electromagnetic interference (EMI).

Limitations:

Moderate Efficiency: Power factor capped at 0.6–0.75, failing to meet high-performance needs.

Bulky Design: Large inductors occupy significant space, unsuitable for compact US electronics like modern laptops or sleek home appliances.

Voltage Sensitivity: Struggles with input voltage fluctuations (e.g., 120V ±10% in the US) and performance drops with load variations.

Common US Applications: Entry-level appliances (e.g., window AC units, basic microwave ovens), low-power power supplies (e.g., <300W desktop PC power supplies), and devices where cost is the primary driver.

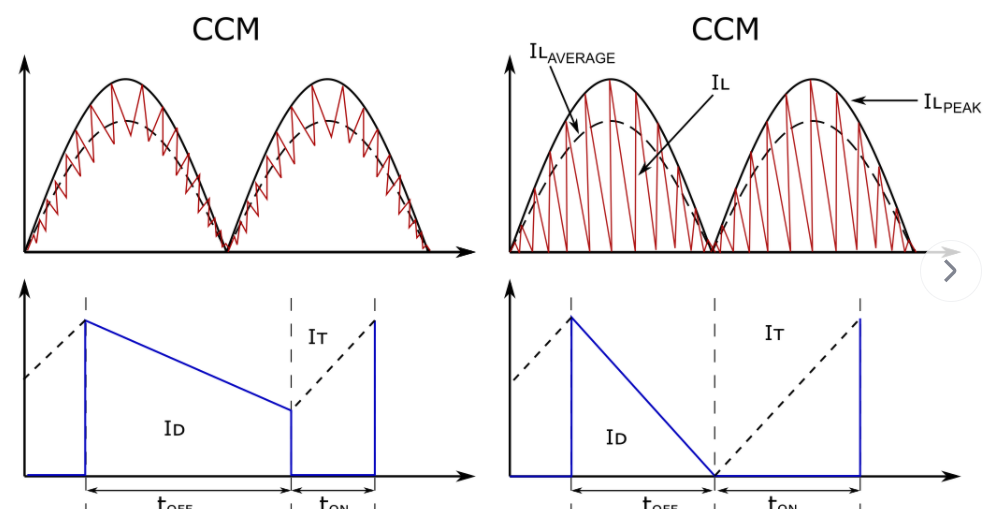

Active PFC employs electronic switches (MOSFETs, IGBTs) and control chips (e.g., TI’s UCC28060, STMicroelectronics’ L6562) to dynamically adjust current waveforms. Using a Boost converter, it boosts input voltage to ~400V while synchronizing current and voltage. Key features:

Advantages:

Exceptional Efficiency: Achieves PF ≥0.99 and total harmonic distortion (THD) <5%, meeting strict US standards like 80 Plus Titanium (94% efficiency at 20% load).

Universal Voltage Support: Handles 90–264V input, ideal for US devices used globally or in regions with unstable grids (e.g., rural areas).

Rapid Adaptability: Instantly adjusts to load changes, critical for servers, medical equipment, and EV chargers with sudden power spikes.

Compact Design: High-frequency operation reduces inductor size, enabling slim profiles for US consumer electronics like 氮化镓 (GaN) laptop chargers.

Challenges:

Higher Cost: 3–5x more expensive than passive solutions due to advanced components and control circuits.

Complex Engineering: Requires precise circuit design and thermal management, raising R&D costs for manufacturers.

EMI Concerns: High-frequency switching may generate interference, necessitating additional filtering components.

Key US Applications: High-power devices (400W+ PC power supplies, server racks in Silicon Valley data centers), industrial machinery (robotics, medical MRI machines), and renewable energy (Tesla Superchargers, SolarEdge inverters for US residential solar systems).

| Metric | Passive PFC | Active PFC |

|---|---|---|

| Power Factor | 0.6–0.75 | 0.98–0.99+ |

| THD | 15%–30% | <5% |

| Voltage Range | Limited (e.g., 120V ±10%) | Universal (90–264V) |

| Efficiency | 70%–80% | 85%–95% |

| Size | Large (bulky inductors) | Small (high-frequency design) |

| Cost | Low (ideal for budget devices) | High (premium applications) |

| US Use Cases | Small appliances, basic PSUs | Data centers, EV chargers, 80 Plus-certified PSUs |

Scenario-Based Recommendations for the US Market:

Consumer Electronics:

Low-Power Devices: Passive PFC for basic chargers (e.g., 5W phone chargers) or entry-level smart home devices (e.g., budget smart plugs).

Premium Electronics: Active PFC for high-power laptops (e.g., Apple 140W GaN charger) and gaming PCs (80 Plus Gold/Silver certified power supplies).

Industrial & Commercial:

Cost-Effective Solutions: Passive PFC for simple machinery (e.g., conveyor belts in US food processing plants).

Critical Systems: Active PFC for medical devices (FDA-approved MRI power supplies) and server farms (ensuring 99.99% uptime in Virginia data centers).

Renewable Energy & EVs:

EV Chargers: Mandatory active PFC for Level 2 chargers (e.g., ChargePoint Home Flex) to meet NEC 625 standards and optimize grid interaction.

Solar Inverters: Active PFC in Enphase microinverters to maximize energy harvest from rooftop solar panels across varying US climates.

Hybrid PFC Solutions:

Combining passive pre-regulation with active fine-tuning, ideal for mid-power applications (500–1000W). Example: US-based APC UPS systems using hybrid PFC to balance cost and efficiency for small businesses.

Wide-Bandgap Semiconductors:

Silicon carbide (SiC) and gallium nitride (GaN) are revolutionizing active PFC. Companies like Wolfspeed (North Carolina) offer SiC MOSFETs that boost efficiency to 97.5% in high-power EV charging stations, reducing heat and size.

Digital Control Dominance:

Digital controllers (e.g., TI’s UCD90160) enable programmable adjustments, real-time diagnostics, and compliance with evolving US regulations (e.g., DOE’s 2023 updates to external power supply standards).

Stringent Energy Standards:

The US 80 Plus program (80 Plus Titanium/Platinum) and ENERGY STAR certifications are driving adoption of active PFC. For instance, a 1000-unit data center using 80 Plus Titanium PSUs saves $12,000 annually in energy costs compared to passive alternatives.

Cost Payback:

A 400W active PFC power supply (vs. passive) saves ~$50/year in electricity (based on US national average $0.15/kWh), paying back the premium in 3–4 years for small businesses. Large data centers see 10x faster ROI.

Carbon Reduction:

A typical US commercial building with 500 active PFC-equipped servers avoids 6 tons of CO₂ annually—equivalent to removing 1.3 passenger vehicles from the road.

Incentives:

Federal tax credits (e.g., Investment Tax Credit for energy-efficient equipment) and state rebates (e.g., California’s IOU programs) further lower the total cost of ownership for active PFC solutions.

High-Power & Efficiency-Critical: Always opt for active PFC (data centers, EV chargers, medical devices).

Budget & Low-Power: Passive PFC suffices for basic appliances and entry-level electronics.

Future-Proofing: Prioritize designs with SiC/GaN compatibility and digital controls to meet upcoming US energy regulations (e.g., 2025 DOE efficiency mandates).

By understanding the technical nuances and US-specific requirements, engineers and businesses can optimize energy use, comply with local standards, and future-proof their designs. As wide-bandgap tech and smart controls mature, active PFC is set to become the default choice for most applications, driving a more efficient and sustainable US power ecosystem.